Francis Turbines

Advanced technology for high sediment environments

Advanced technology for high sediment environments

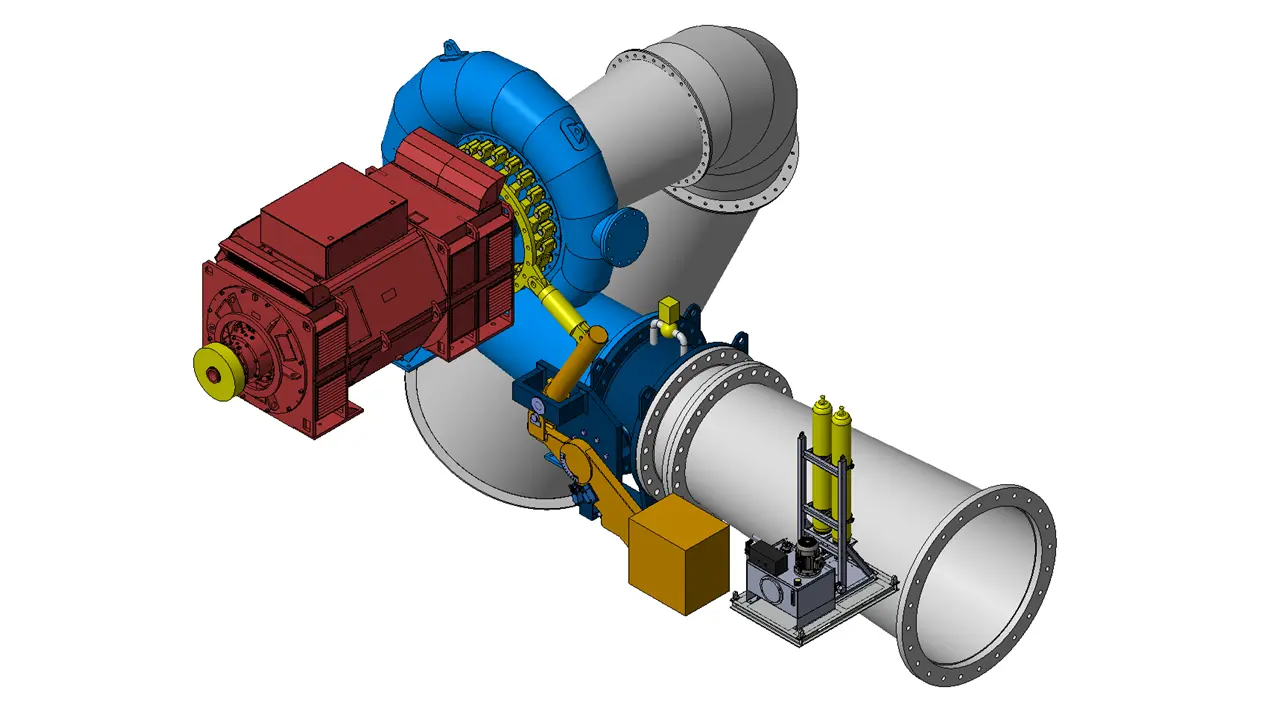

DyneVec delivers optimized hydro turbines for rivers with high sediment loads or clean water. New projects and refurbishments.

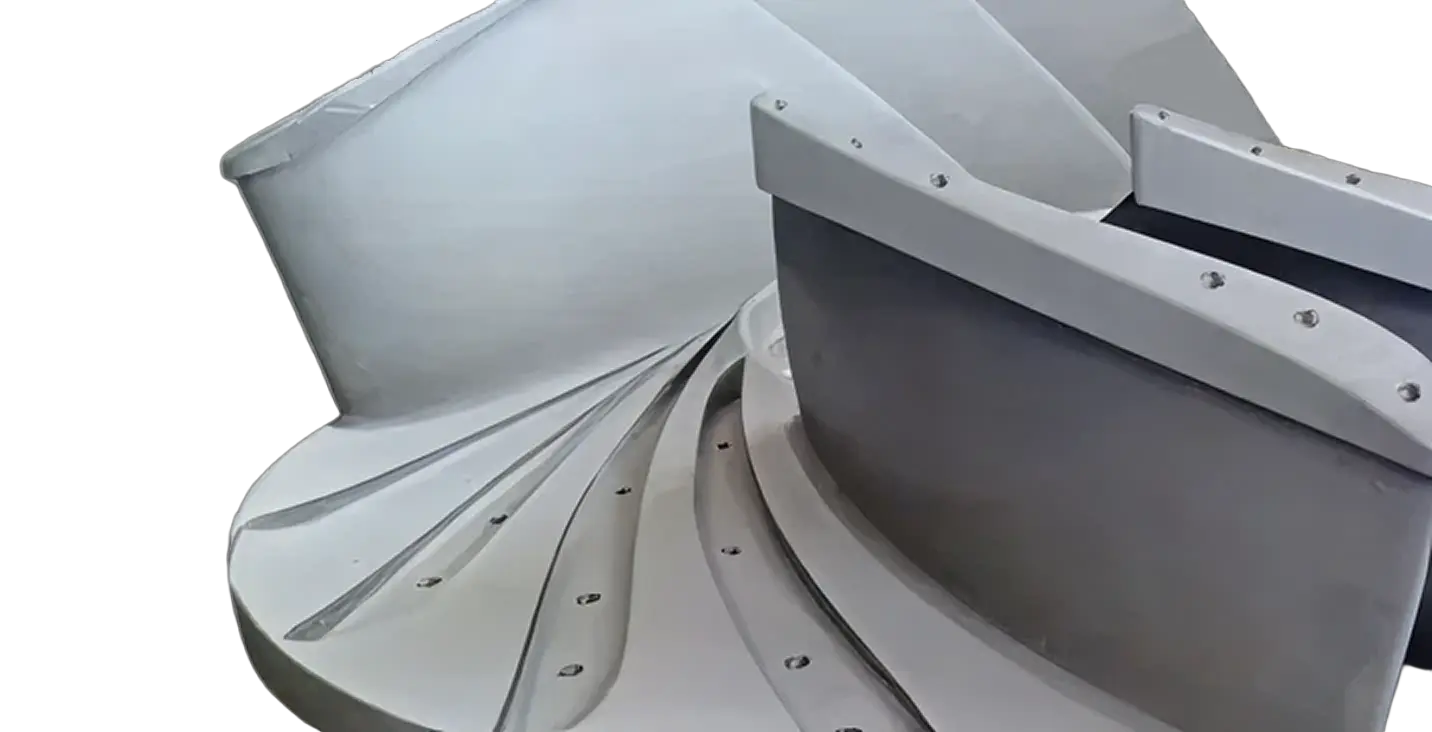

The patented, Monsoon Runner® technology consists of separate crown, band and blades that are bolted together instead of being welded as for at traditional runner. This gives the Monsoon Runner® the advantage that hard coating can be applied on 100% of the wetted surfaces with excellent long-lasting quality, giving it the best protection against erosion available in the market.

The runner vanes are machined with flanges both towards the crown and band side. The crown and band have a set of grooves for the runner vanes, which have flanges that fit into the grooves. This innovative design ensures optimal performance while allowing for easy maintenance.

The bolted runner from DynaVec can easily be assembled and disassembled by standard hand tools. This can be performed on-site if a lifting arrangement is present.

Partly assembled Bolted DynaVec runner

Fully assembled Bolted DynaVec runner

As the runner can be separated, all wetted surfaces can easily be HVOF coated. The thermal spray coating (HVOF - High Velocity OXY-Fuel) is applied with robots. Typical coating thickness will be between 0.2 – 0.3 mm.

There are two types of maintenance for the bolted runner. The most efficient is preventive maintenance, where sandblasting and recoating are performed before the coating surface is broken. The alternative is to reshape the geometry if it is damaged before coating, as normally in a planned maintenance schedule. Since the bolted runner can easily be disassembled, this simplifies maintenance and repair compared to a welded runner.

Contact our experts to learn how DynaVec's Francis Monsoon Runner® can improve your plant's efficiency and reduce maintenance costs.

Contact Us