Pelton Turbines

Advanced technology for high sediment environments

Advanced technology for high sediment environments

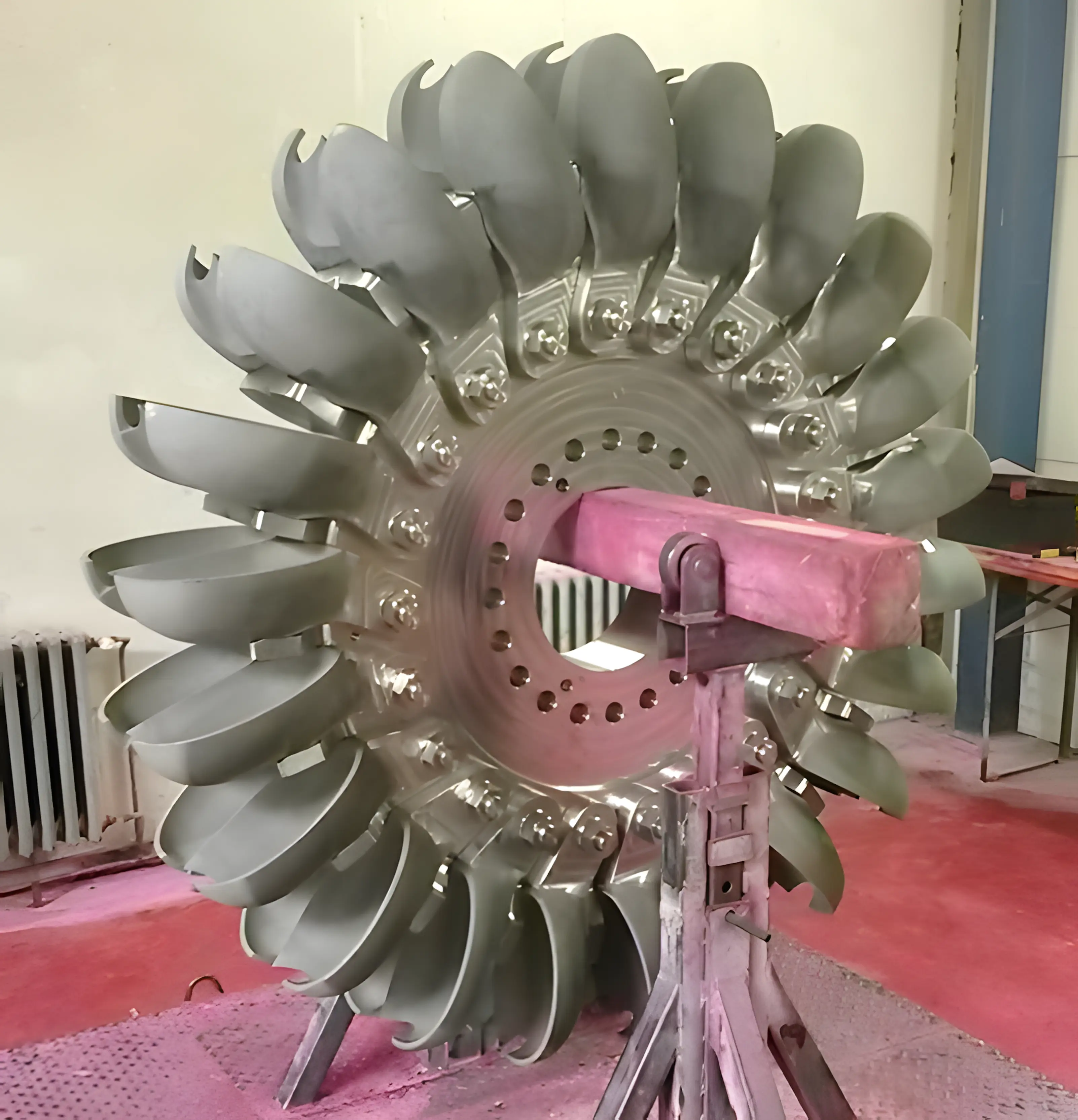

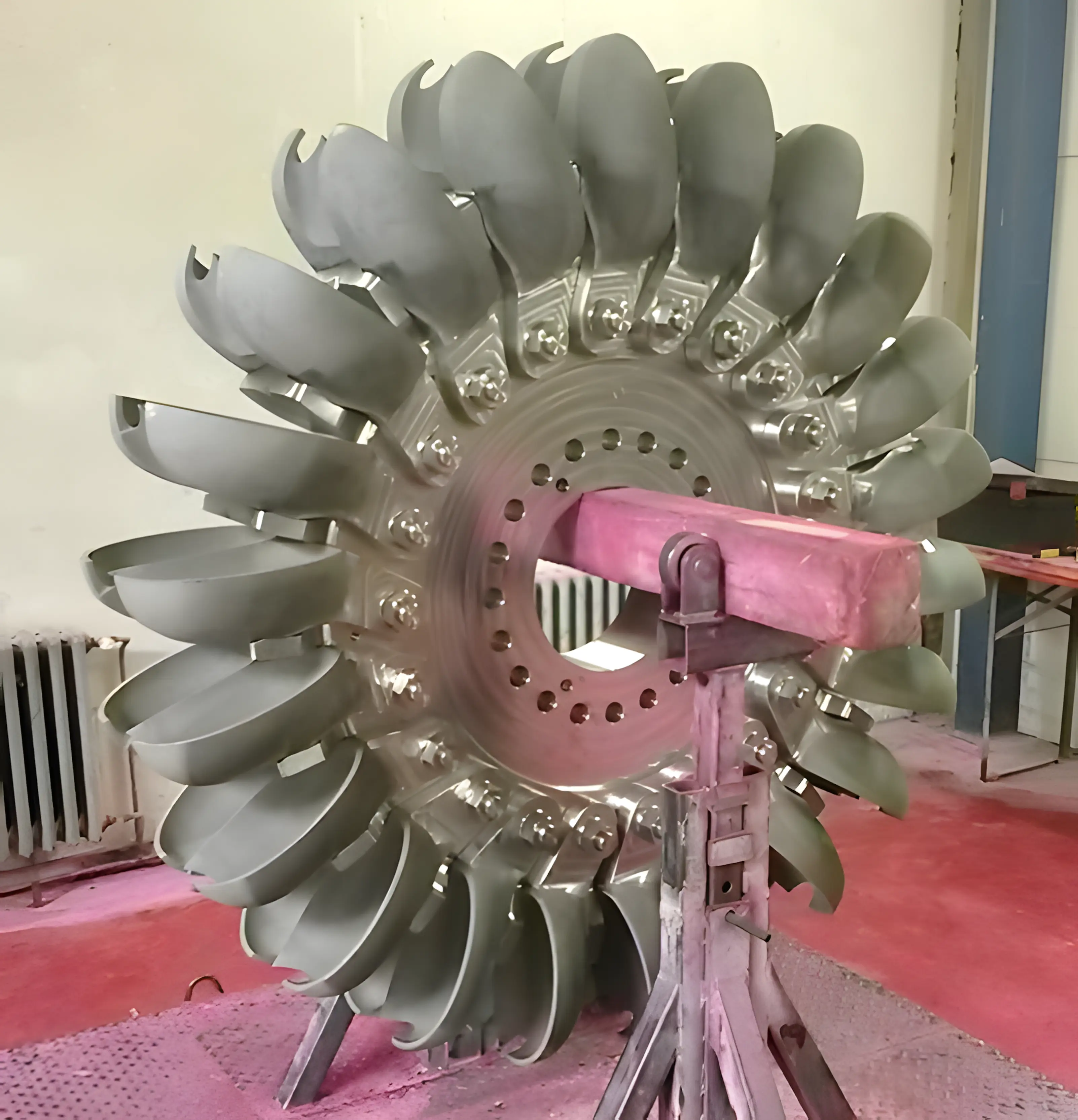

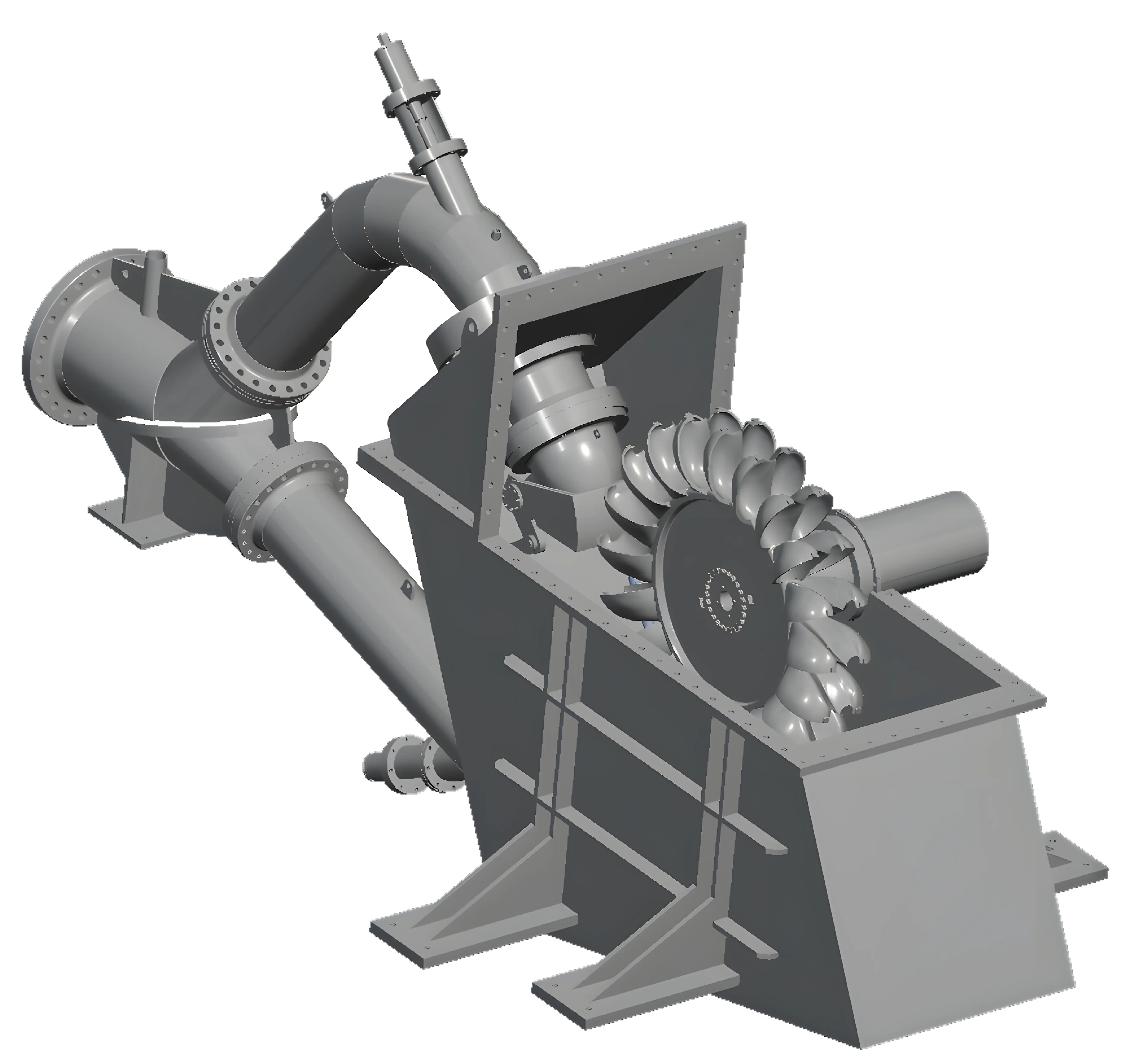

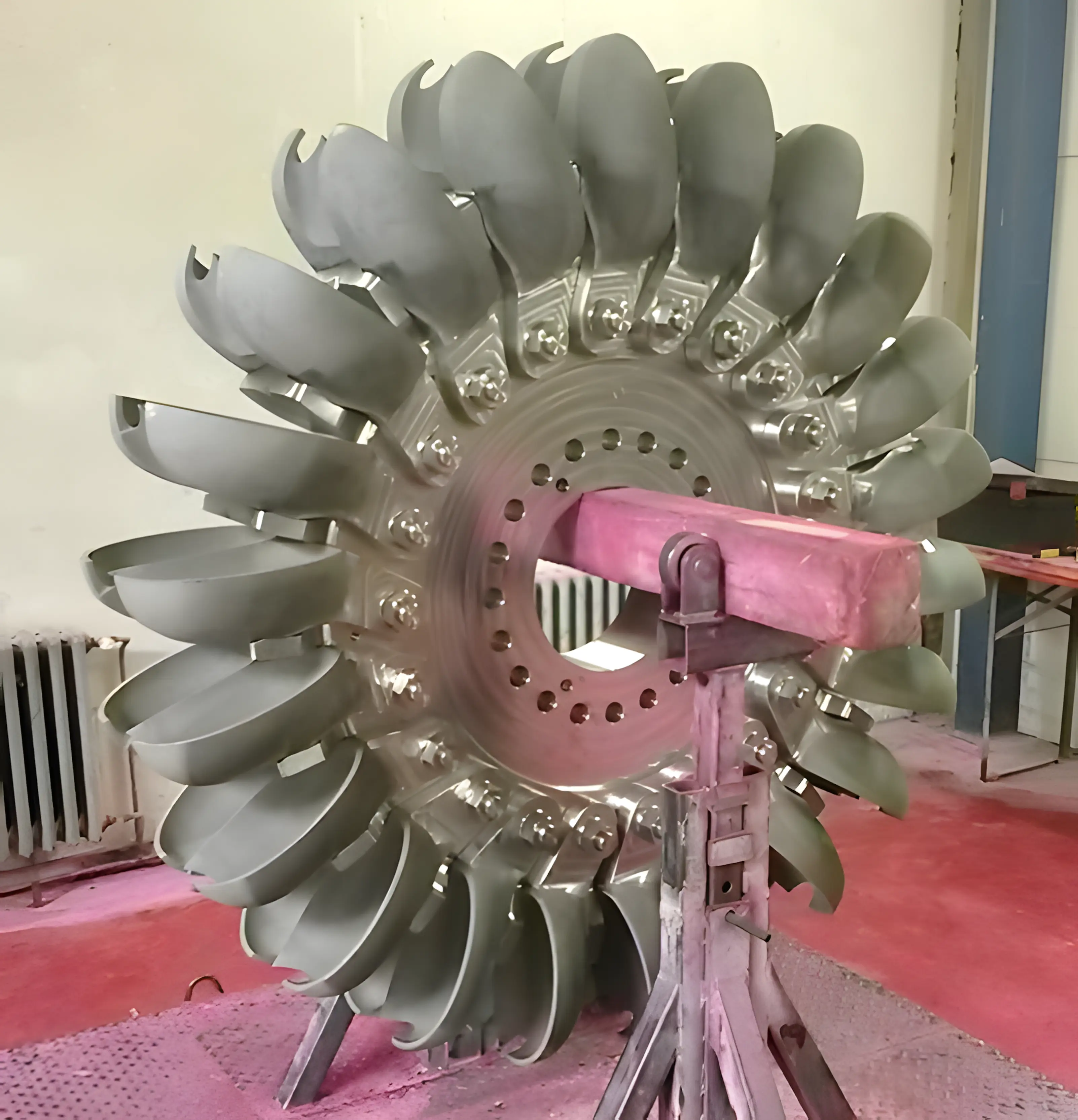

DynaVec AS offers innovative solutions for Pelton turbines exposed to water with high sediment content. All areas with high water speeds will be fully protected with hard-coating (HVOF - Wolfram Carbide). This includes the nozzles, needles and the patented runner described below.

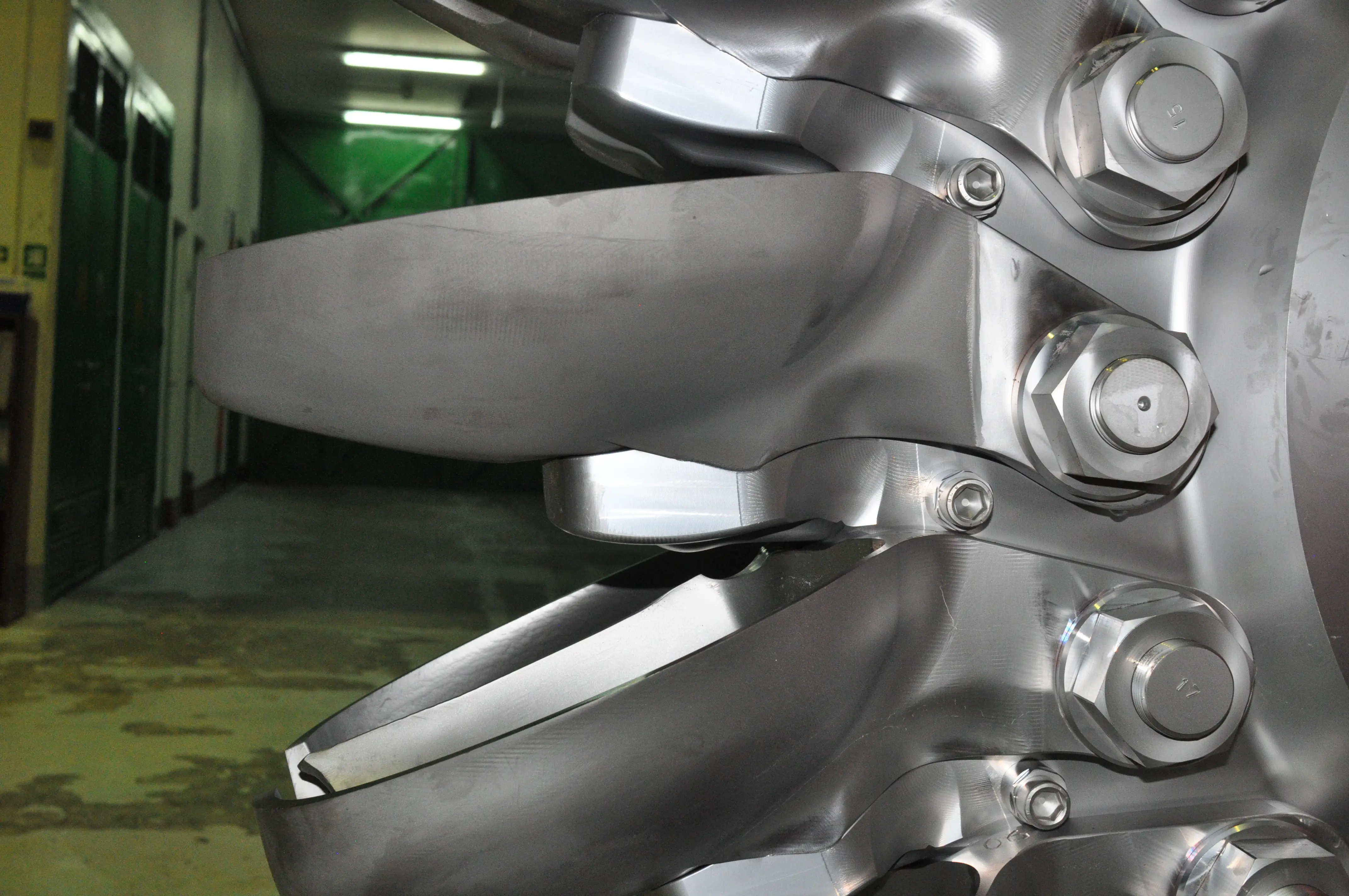

With our patented, easily exchangeable Pelton bucket design, you can quickly swap out and HVOF coat the buckets, ensuring minimal downtime and maintaining peak performance. By investing in our state-of-the-art design, you not only enhance the longevity of your equipment but also save time and resources on maintenance.

The DynaVec Pelton runner consists of a separate disk and the optimal number of replaceable buckets connected to the disk, each by only one bolt. This allows for easier access to fully apply hard coating (HVOF) on the wetted surfaces and the possibility of easily exchanging the buckets as spare parts.

As the runner can be separated, all wetted surfaces can easily be HVOF coated. The thermal spray coating (HVOF - High Velocity OXY-Fuel) is applied with robots.

Contact our experts to learn how DynaVec's Pelton Monsoon Runner® can improve your plant's efficiency and reduce maintenance costs.

Contact Us